Universal

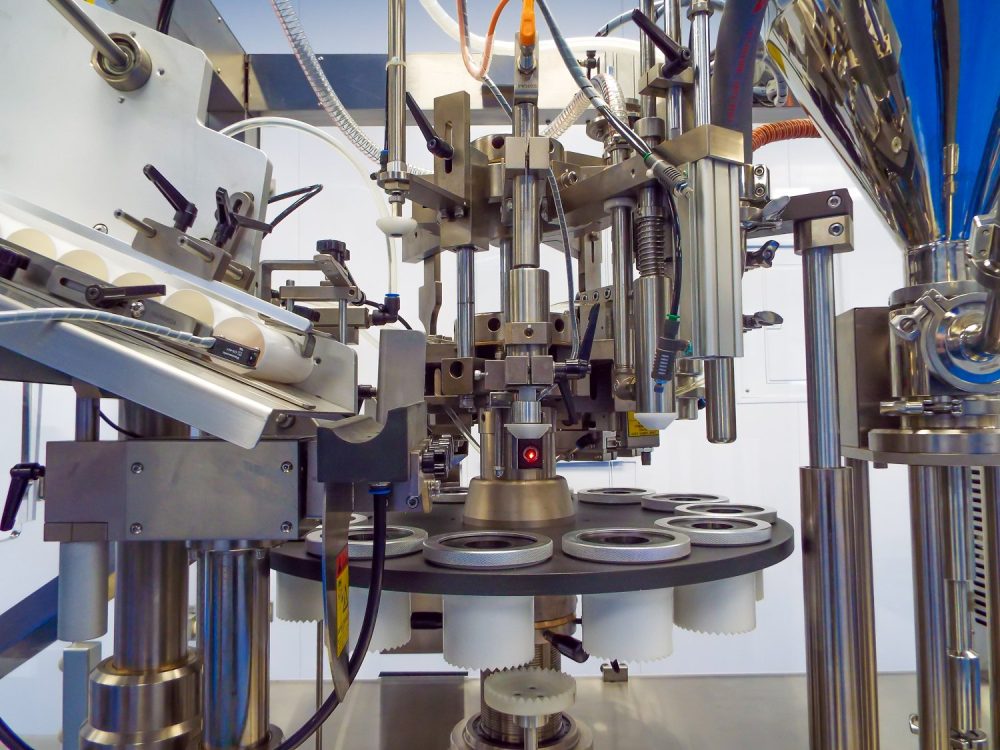

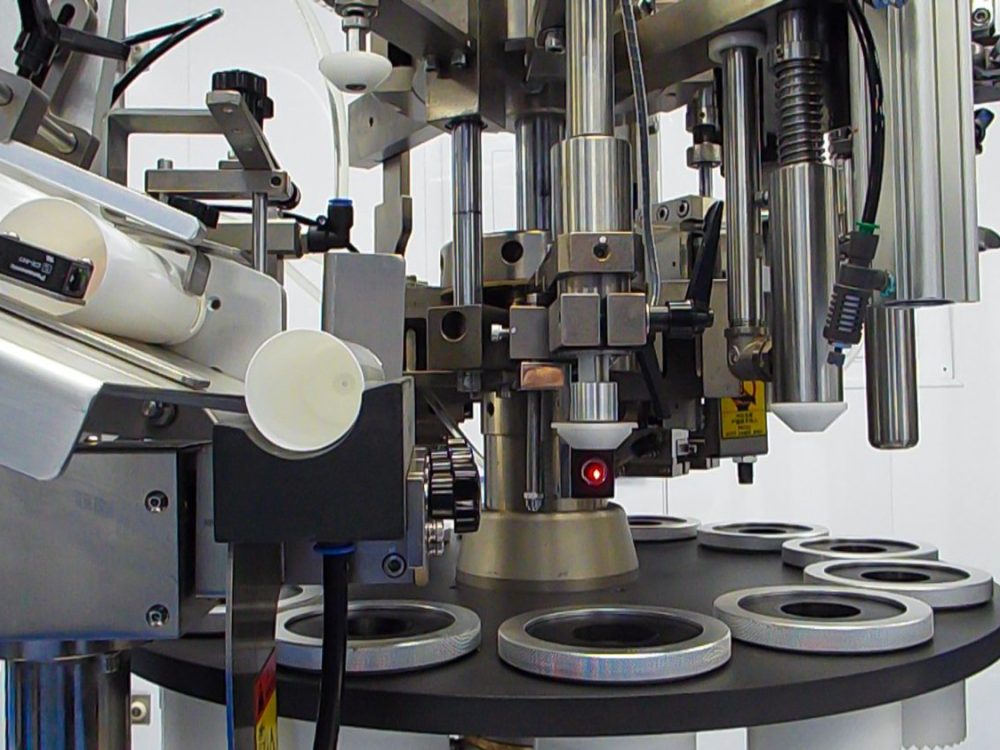

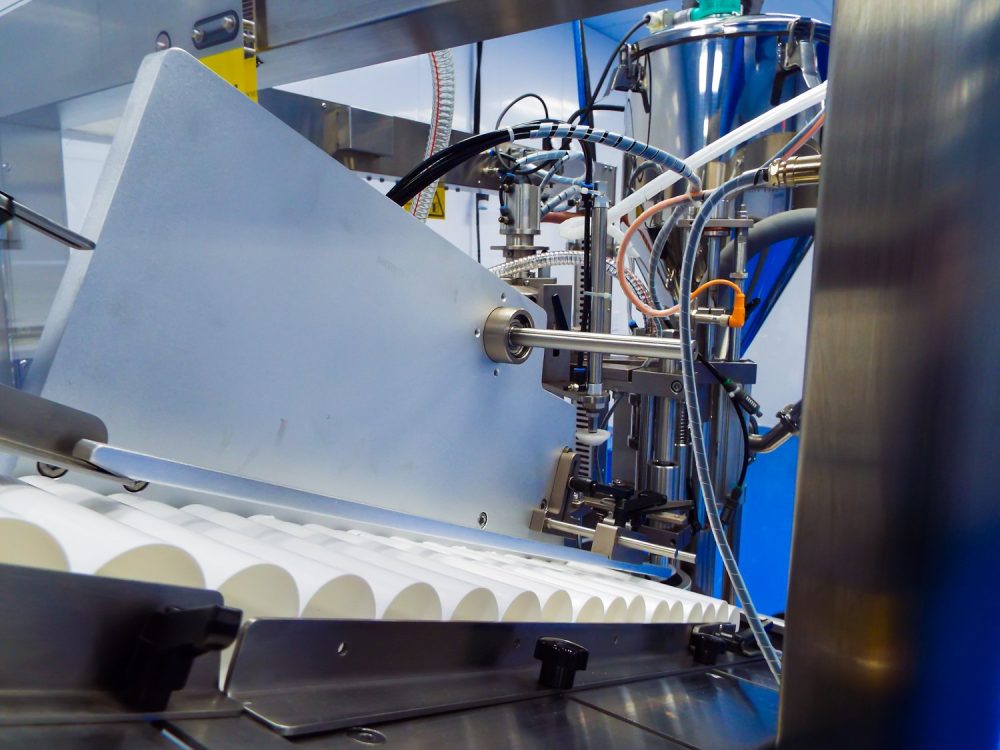

Tube Filling and Sealing Machine

USA based Service Technicians, Spare Parts, and Tooling

Key Features

Speed

Output of up to 80 tubes per minute, 4,800 tubes per hour, 34,000 tubes per shift.

Versatility

Changeover from plastic or laminate tube sealing to metal tube crimping on the same machine.

Built to Last

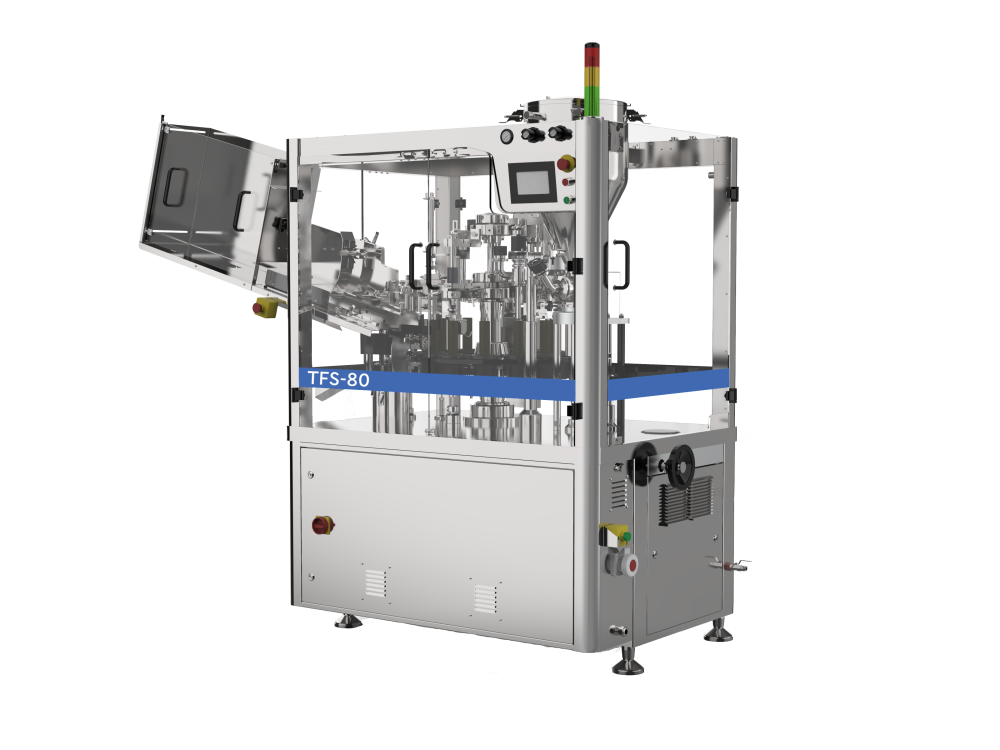

High quality 304SS construction. Product contacting wet parts made from 316 stainless steel.

Ease of Use

Capable of being run by a single operator. The touchscreen Mitsubishi PLC is used to save filling and sealing parameters.

Accuracy

Rest assured knowing tubes are filled within

< ± 1% of the desired volume.

Professional Quality

Achieve perfect tube seals with hot air technology and dual sided coding or saddle-fold crimping.

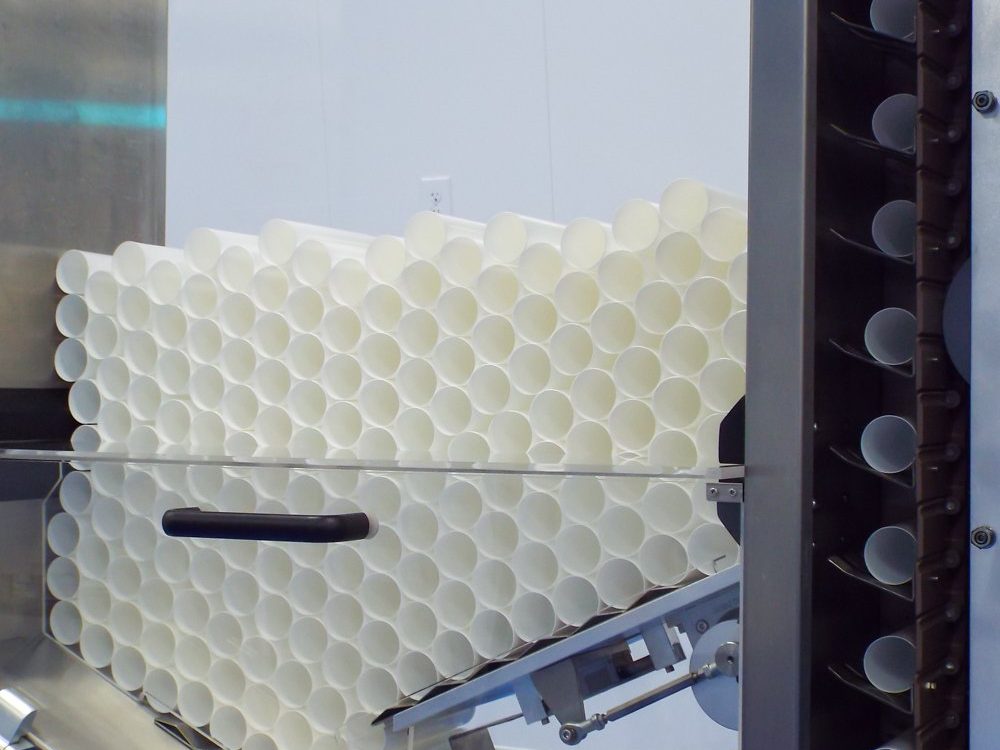

Tube Filler Features:

- Speed: 80 Tubes Per Minute

- Sealing: Hot Air Sealing

- Touch Screen PLC

- Preset tube sealing settings

- Automatic Cassette Tube Feeding

- Automatic Tube Discharge

- Automatic Tube Orientation

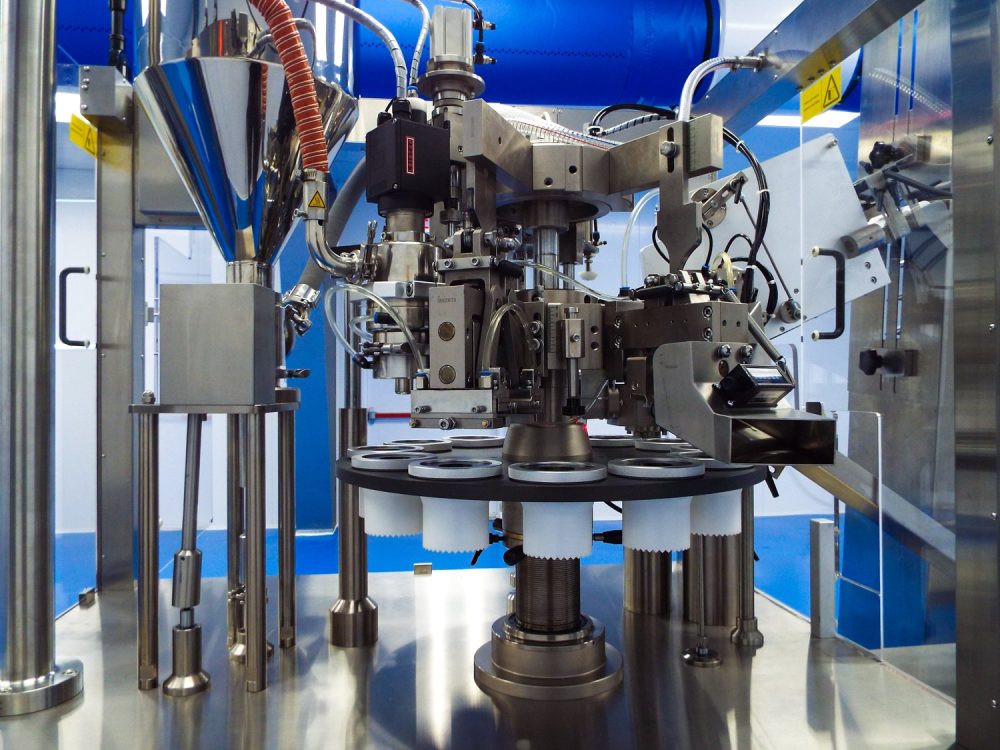

- 12 Station Rotary Indexing

- Bottom-up Filling with diving nozzle

- Filling Nozzle with cut-off and air blow

- No Tube No Fill safety

- Rapid Change Over, easy cleaning

- Rapid Delivery size parts tooling

- Stainless Steel Contact Parts

Tube Filler Specifications:

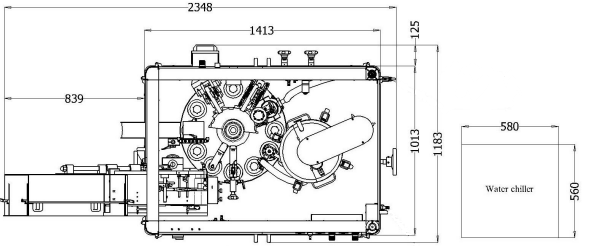

- Tube Diameter: 10mm – 55mm

- Tube Length: 230mm (max tube O.A.L.)

- Filling Volume: 5 – 300ml

- Filling Accuracy: +/- 1%

- Hopper Volume: 40 Liter

- Main Motor 2 HP (1.5kw)

- Electrical: 220V, 3 Phase, 20A, 60Hz

- Electrical Requirements: 5.4kw

- Air Pressure: 87-116 PSI (0.6-0.8 Mpa)

- Air Volume: 238 gallons/min (900 L/min)

- Chilled Water Temperature: (15-20°C)

- Max Hot Air Temperature: (600°C)

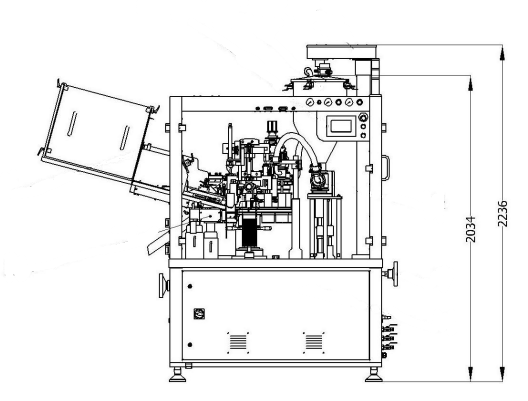

- Dimensions: 95” wide x 45” deep x 90” tall

- Weight: 3,300 lbs (1,500 kgs)

Top Quality Components:

- PLC: Mitsubishi (from Japan)

- Touch Screen LCD: Weinview (from Taiwan)

- Variable Frequency Drive: Delta (from Taiwan)

- Servo Motor: Mitsubishi (from Japan)

- Orientation Sensor: Panasonic (from Japan)

- Power Switch: Omron (from Japan)

- Solid State Relay: Omron (from Japan)

- Proximity Switch: Sick (from Germany)

- Emergency Stop: Schneider (from France)

- Power LED: Schneider (from France)

- Power Switch: Schneider (from France)

- CAM Switch: Moullar (from Germany)

- Pneumatic Cylinders: SMC (from Japan)

- 316L Stainless Steel contact parts