Multi-SKU speed

Output of up to 30 tubes per minute, 1,800 tubes per hour, 13,000 tubes per shift. Multiple SKUs per day, higher profit margins on short-run, high-mix production.

Universal Usage

Fill and Seal all tube materials, shapes, and sizes on the same machine. Plastic, Laminate, IML, Aluminum tubes; round, oval, flat shapes and custom cap designs.

Rapid Changeover

Switch between tube sizes, tube materials and filling products in a few minutes, no tools required. Industry best uptime and ROI.

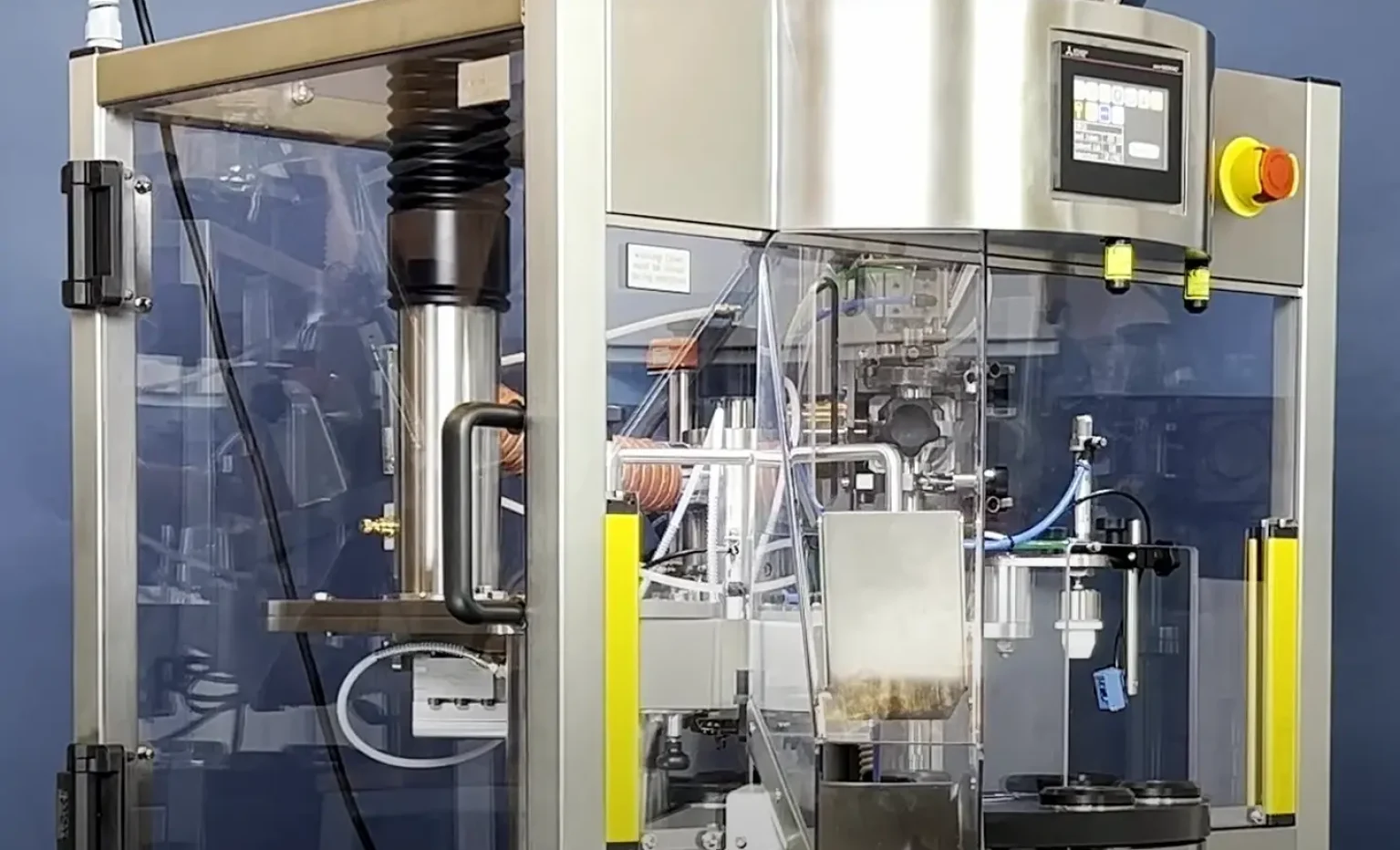

Ease of Use

A single operator can run production, no mechanics needed. Simple setup and changeover with electronic tube fill-seal recipes saved in touchscreen menu.

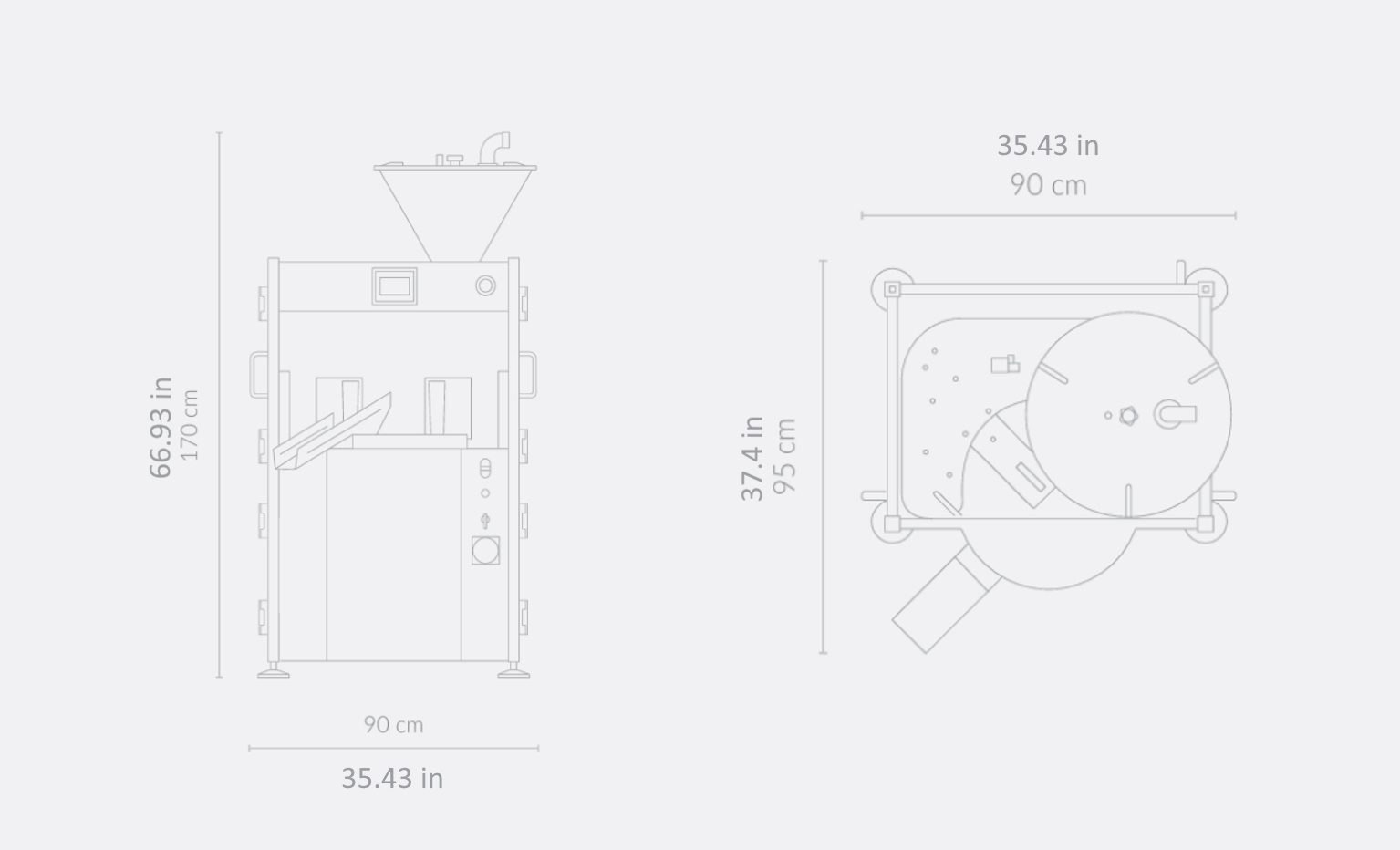

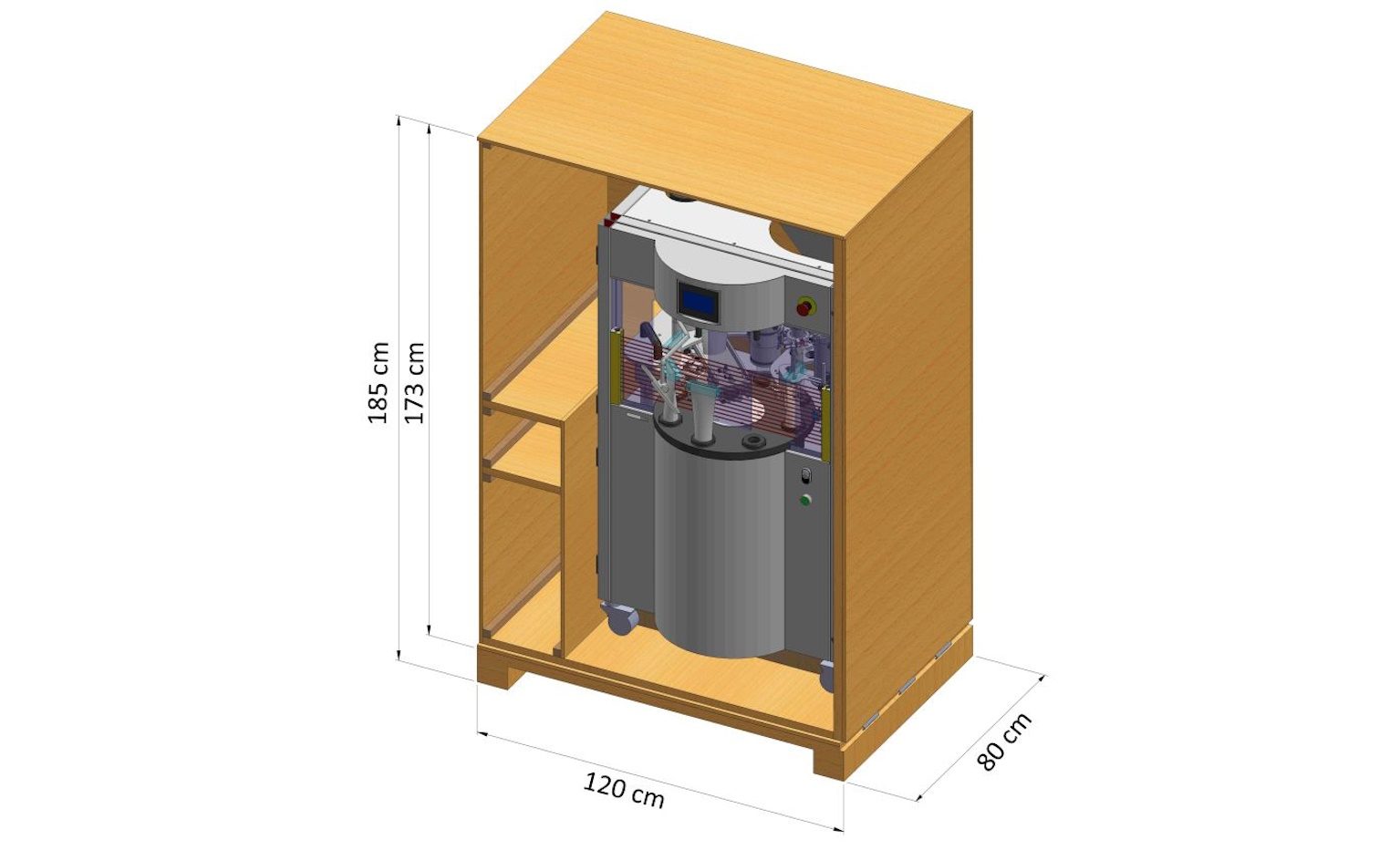

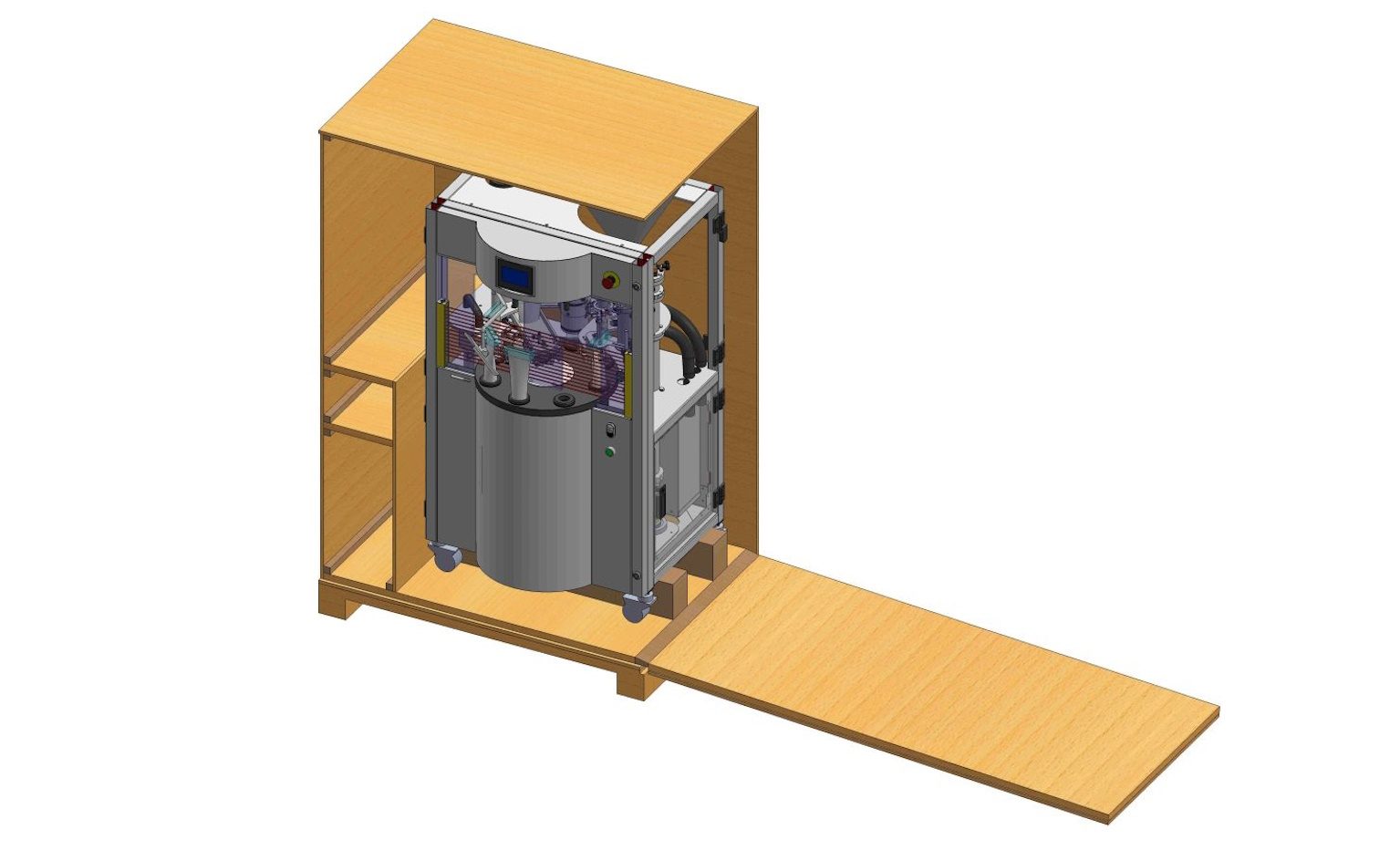

Compact Footprint

Minimum floor space required, maximizes profits per square foot. Easy to move between production rooms and labs, compact size fits thru a standard door opening.

Highest Quality

Built in Europe to pharma grade standards with top shelf components and craftsmanship. Designed for utmost reliability and minimal maintenance over many years of production use.

More Videos

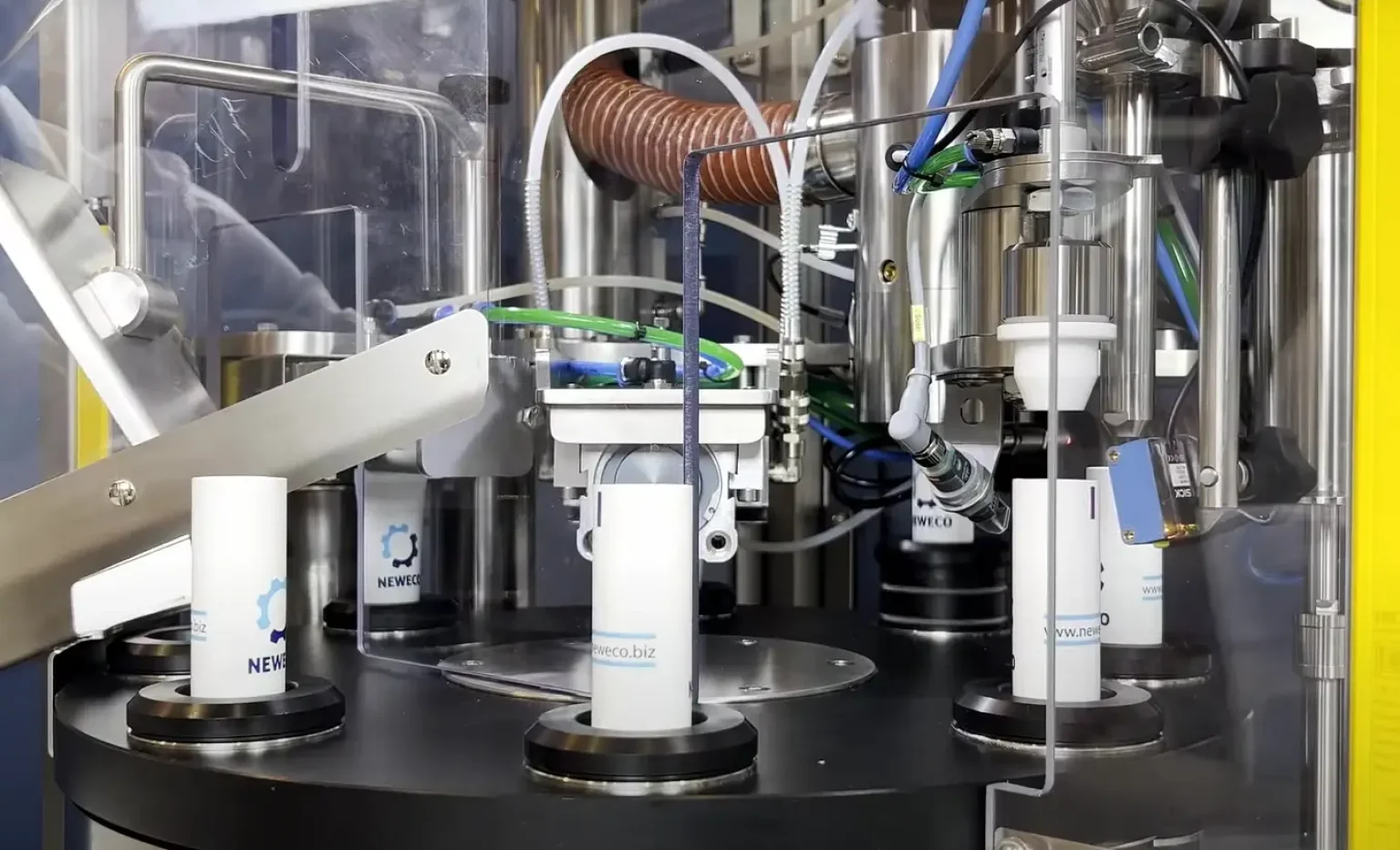

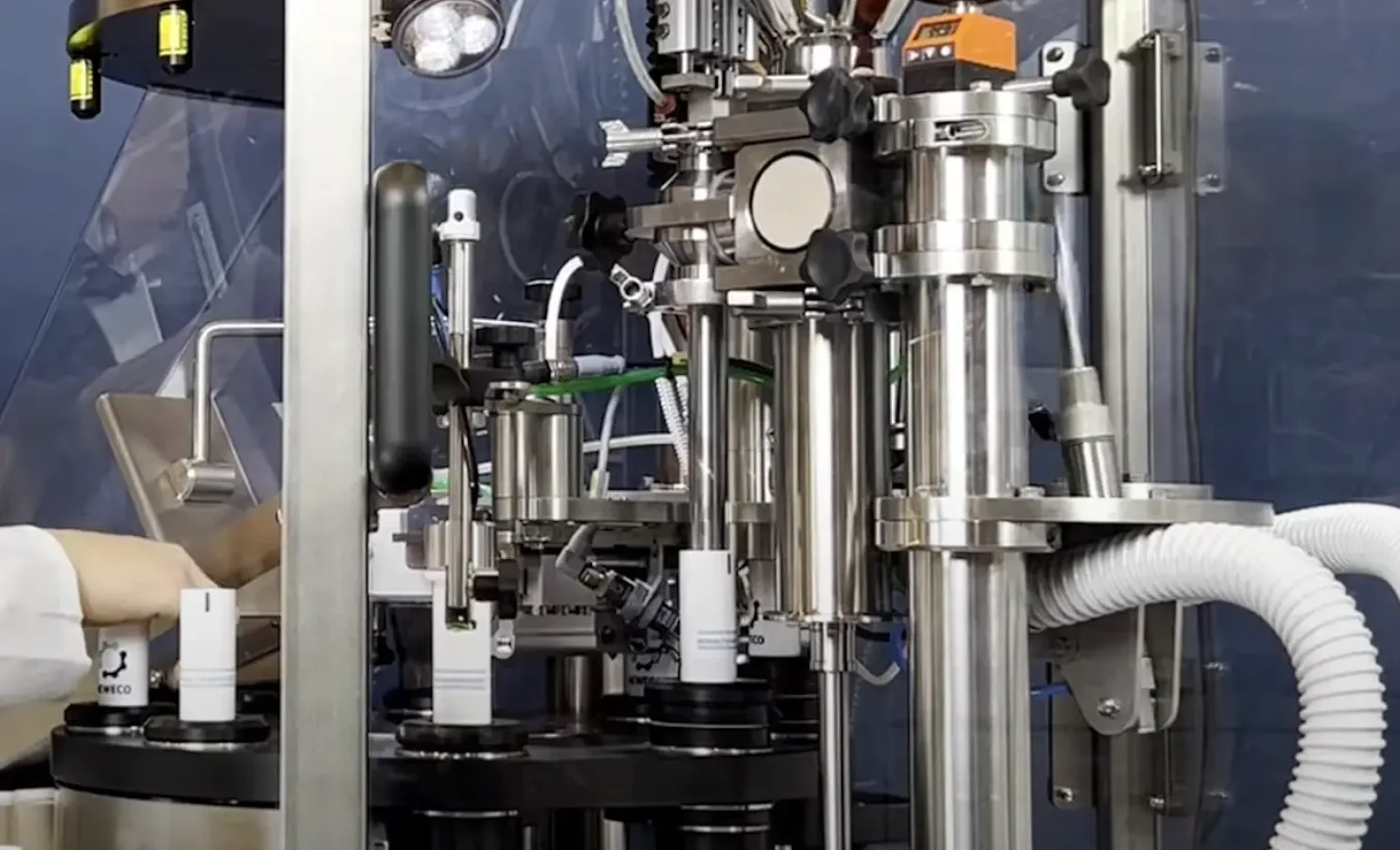

Tube Filler Features:

- Speed: 30 Tubes Per Minute

- Sealing: Hot Air Sealing technology

- 8 Station Rotary Table

- Automatic Tube Orientation

- Automatic Tube Filling

- Automatic Tube Sealing

- Automatic Tube Coding

- Automatic Tube Trimming

- Automatic Tube Discharge

- Electronic Saving of tube recipes

- No Water Chiller required

- Integrated Tube Seal Tester

Specifications:

- Tube Diameter: 10mm – 60mm

- Tube Length: 250mm (max tube O.A.L.)

- Filling Volume: 3 – 260ml

- Micro-dosing Volume: 0.4 – 10ml

- Filling Accuracy: < +/- 1%

- Hopper Volume: 25 Liter

- Electrical: 220-240V, 1-phase, 2.8kW

- Air Pressure: 87 PSI (0.6 MPa)

- Air Volume: 106 gallons/min (400 L/min)

- Max Hot Air Temperature: (600°C)

- Dimensions: 35.4” W x 37.4” D x 66.9” H

- Weight: 628 lbs (285 kgs)

Top Quality Components:

- Stainless steel AISI 304 construction

- Contact parts from AISI 316 stainless steel

- Mitsubishi Electric PLC and touch screen

- Mitsubishi Electric rotary drive

- Festo, CKD, Camozzi pneumatic elements